Overview

Energy Resources Consulting Pty Ltd (ERC) provides analytical and consultancy services to the fossil fuel exploration and extraction industries. Their services include gas in coal testing, coal property testing, coal petrography and pyrolysis measurement. ERC have a number of high pressure gas Rigs used to test coal samples for gas content and other properties. The results allow their customers to assess the value of potential mine sites.

To determine the adsorption of a sample, or in other words the amount of gas storage within the sample, the following very simplified test method is executed:

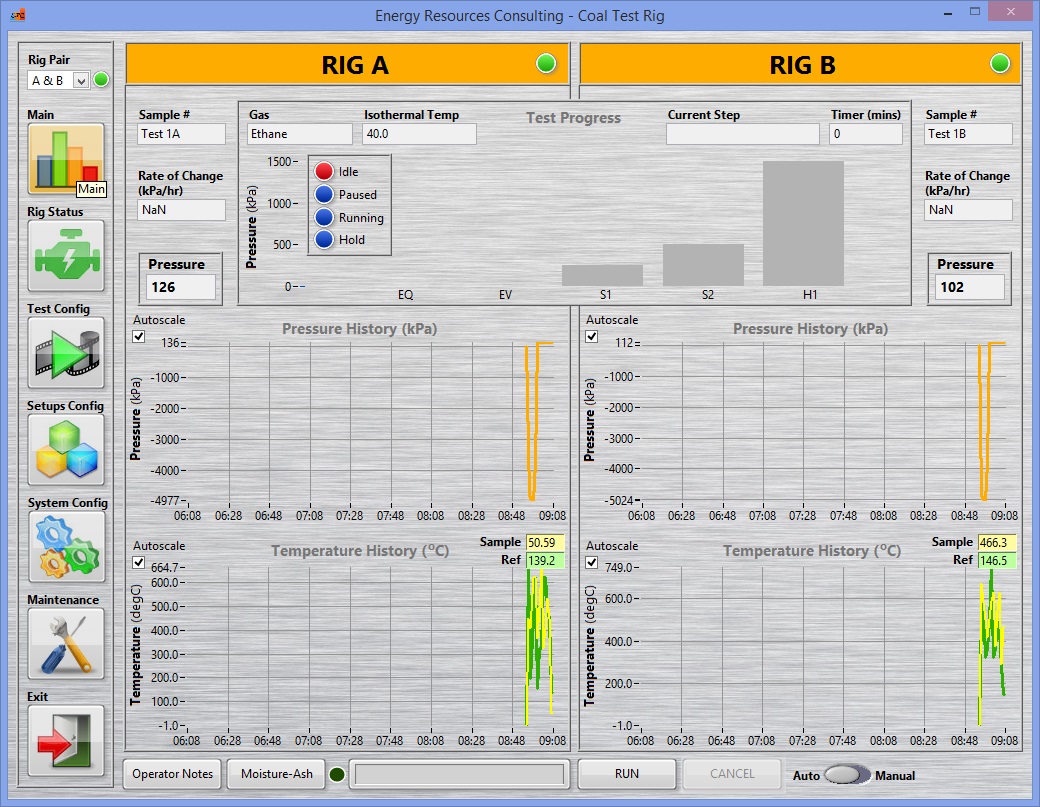

- Set temperature in chamber and wait for equalisation (a few hours)

- Evacuate all gas in system

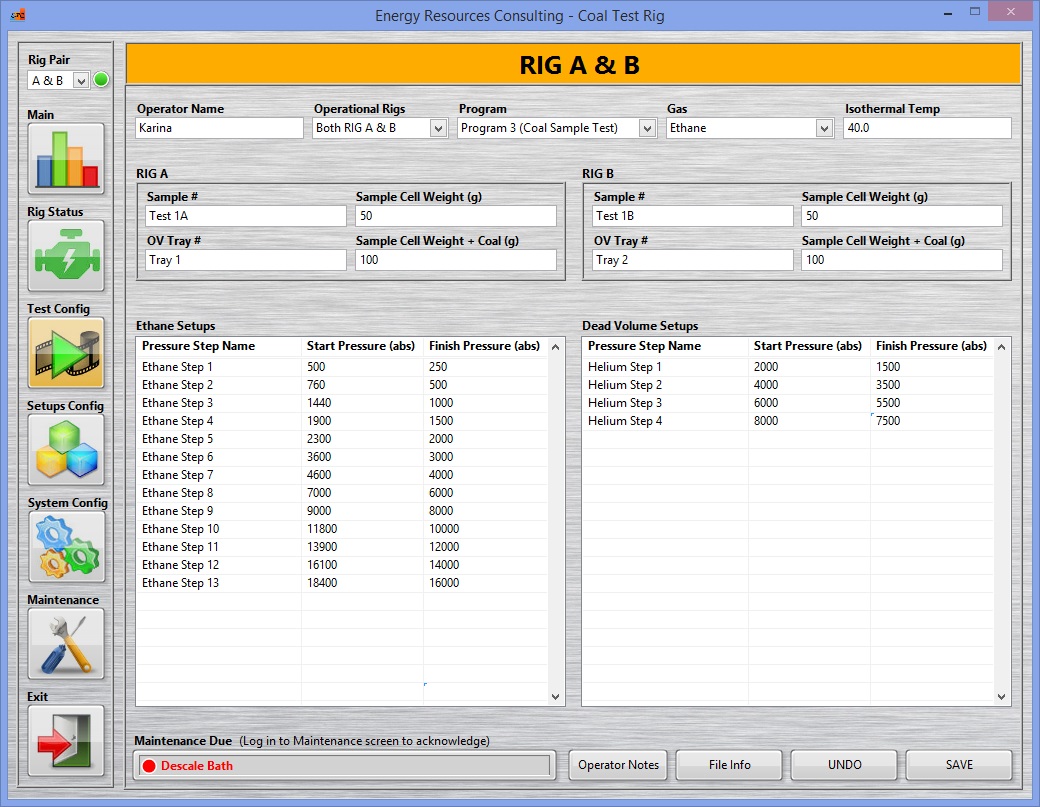

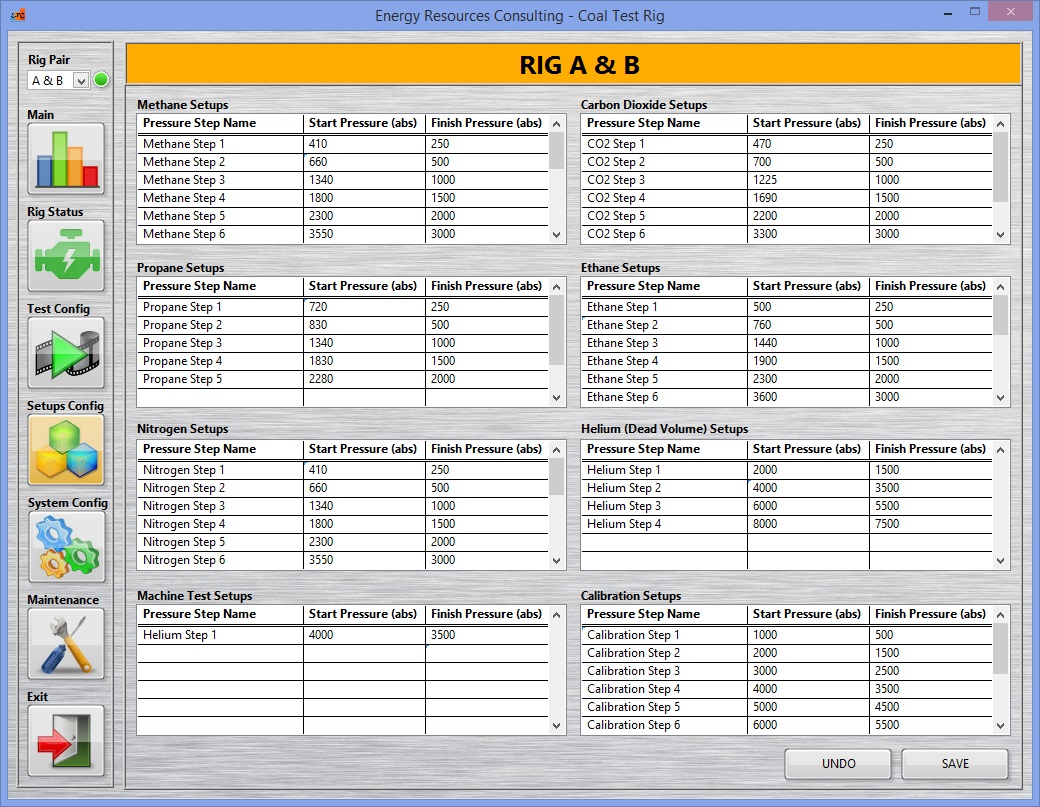

- Perform up to 15 pressure step measurements using selected adsorbing gas (Methane, Carbon Dioxide, Propane, Ethane….). Each step requires the system to reach temperature and pressure stability, which takes a few hours.

- Perform 4 pressure step measurements using anon-adsorbing gas to determine the “Dead Volume” or free volume of the system not occupied by the sample.

Given this test procedure, a single test takes up to 3 days to complete, and could not proceed from one step to the next while the operator was not present, extending the test times considerably.

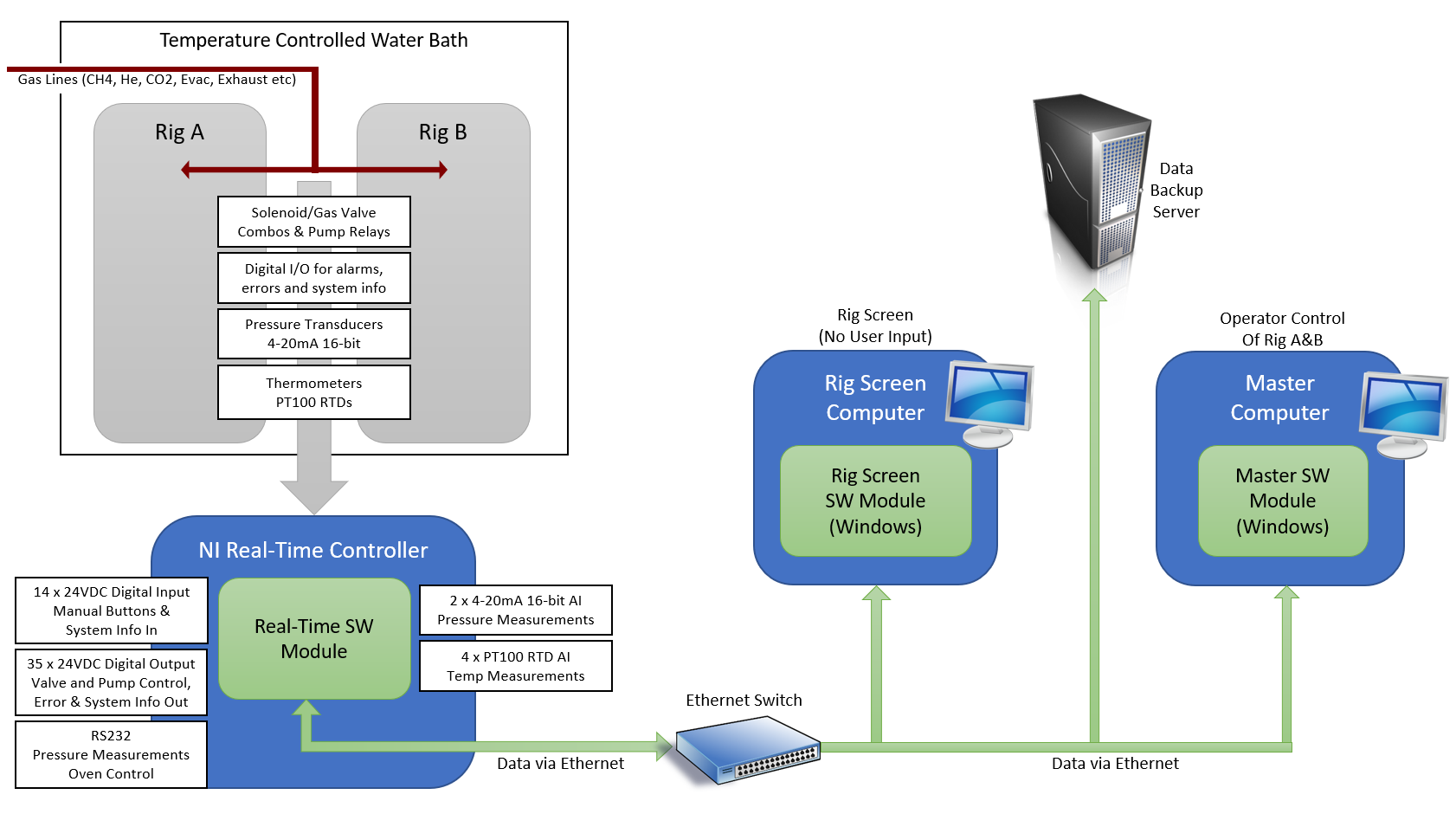

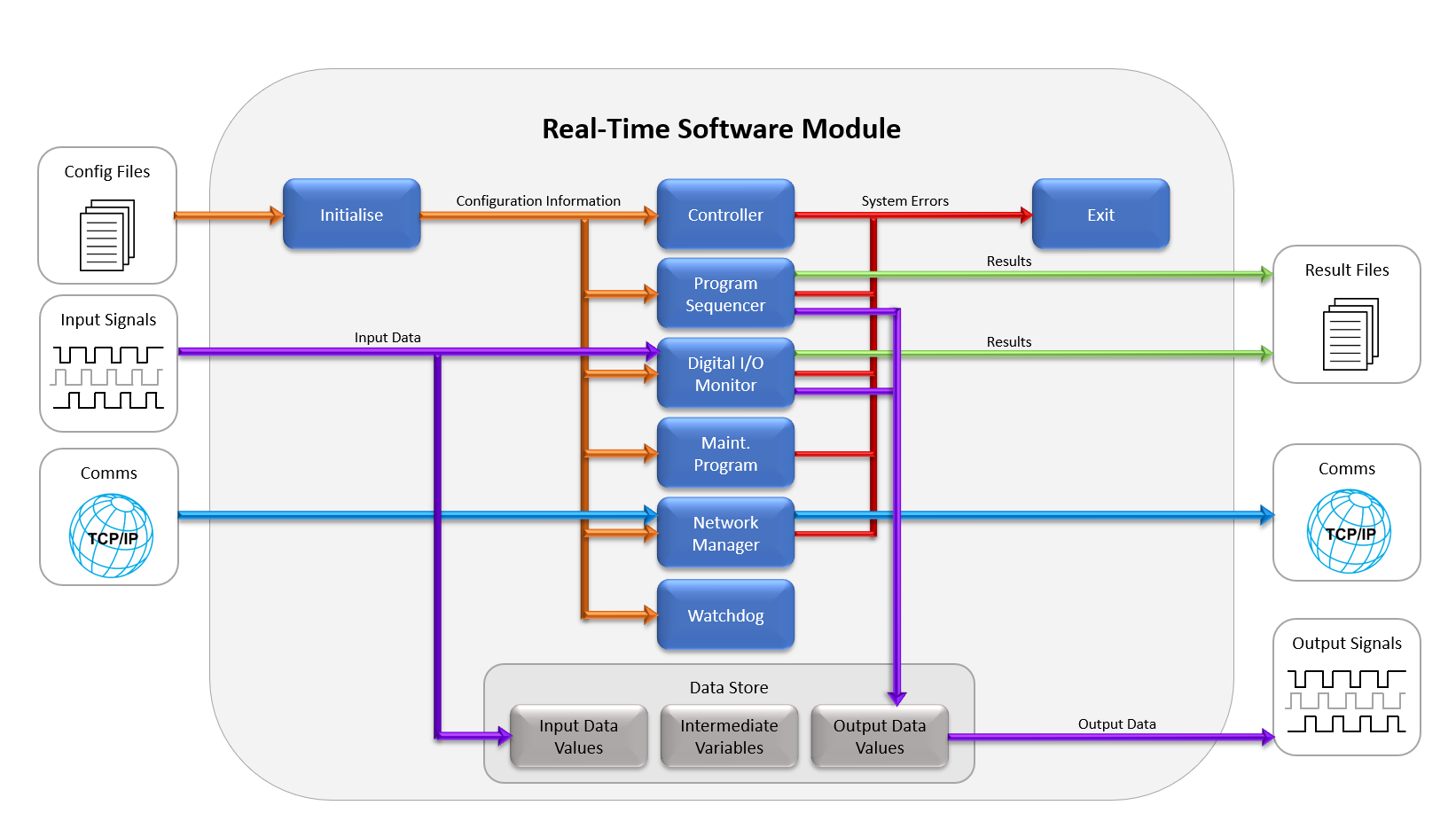

ERC approached EnvisEng, a National Instruments Alliance Partner, to design and develop a real-time control and monitoring system to automate their test process, in an effort to reduce test times, minimise the number of operators required, eliminate operator mistakes and increase test accuracy.

Outcome

The solution developed by EnvisEng using LabVIEW and the National Instruments cRIO platform allows Energy Resources Consulting to continually run two sets of coal sample tests in parallel, managed by a single cRIO, with out operator input after test start. This allows tests to run after-hours without operator supervision, and tests are completed in less than half the time. The maintenance time for the system is now lower, and the automated system has been proven to reduce human error when compared to manual test methods – decreasing the need for sample re-test. These factors combined greatly diminish the time and cost of coal sample testing for ERC.

This project was initially attempted by ERC using internal resources without success, but the software development and design expertise provided by EnvisEng allowed the project to run to completion, on time and budget, meeting all requirements of the initial system specification.

The completed system has been so successful that there is potential to duplicate the system multiple times for increased testing capacity at ERC, as well as for international clientele.

Visit Energy Resources Consulting Pty Ltd (ERC) for more details